HSS M35 TAPER SHANK TWIST DRILL LONG SERIES DIA 14 MM, FL 142 MM , OAL 223 MM , MT1 AS PER IS:8305

- Stock: 10

- Model Number: HSSM35TS14X142X223XMT1XIS8305

- Weight: 1.00kg

- Dimensions: 14.00mm x 142.00mm x 223.00mm

“SHIVMAC” Make

HSS M35 TAPER SHANK TWIST DRILL LONG SERIES DIA 14 MM, FL 142 MM , OAL 223 MM , MT1 AS PER IS:8305

Model No. : HSSM35TS14X142X223XMT1XIS8305

About The Drill :

1.

High Performance High Speed Steel Twist Drill ( Taper Shank

).

2.

Uncoated with Hardness on Cutting Edges 62 to 64 HrC.

3.

Universal Geometry for all types of Metal Application –An

all round performing grade.

4.

Helix Angle 30° - Most suitable for all types of Milling

applications.

5.

Made from Finest Grade of High Speed Steel - M35 GRADE

6.

With Morse Taper Shank most suitable for all types of

Conventional & Advanced latest drilling machines.

7.

Single piece plastic box packing to avoid transport

breakage/chip off.

8.

Un -Identical & Unique Tool number Laser marked on each

tool for correct traceability.

9. M35 ( MAC 200 Grade ) of HSS Chemical composition as per below detail

| C | Si | Mn | P | S | Cr | Mo | V | W | Co |

|---|---|---|---|---|---|---|---|---|---|

| 0.88-0.95 | 0.40 max | 0.40 max | 0.030 max | 0.030 max | 3.80-4.50 | 4.75-5.20 | 1.75-1.90 | 6.00-6.70 | 4.60-5.00 |

11. Two-Piece

Construction: The

term “two-piece construction” typically refers to the fact that the taper shank

drill consists of two main parts, The Shank: This is the tapered portion that fits into the

spindle or chuck of the drilling machine which is made of Normal Steel & The Fluted Body: The fluted body contains the cutting edges

(flutes) and is responsible for removing material during drilling which is made of High Speed Steel. Both

the pieces are butt welded together by way of maintaining concentricity &

minimum runout.

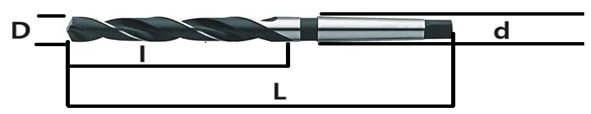

Drawing of The HSS Taper Shank Twist Drill : à

|

Cutting Diameter (D) |

Cutting Length (I) |

Over All length ( L) |

Shank Diameter (d) |

Number of Flutes |

Coating Type |

Shank Type |

|

|

14.00 mm (h7) |

142 mm |

223 mm |

MT-1 |

02 |

Uncoated |

Tanged Shank |

|