MICRO GRAIN SOLID CARBIDE CENTRE CUT TIALN COATED ENDMILL DIA 10MM X CR 2MM X SHANK DIA 10MM X CEL 22MM X OAL 72MM 4F, 30° HELIX ANGLE

-550x550h.jpg)

- Stock: 25

- Model Number: SCCREM10X22X72X10XTIALNX2CR

- Weight: 0.10kg

- Dimensions: 10.00mm x 22.00mm x 72.00mm

“SHIVMAC” Make

MAC2000ECO Grade - Solid

Carbide Endmills - Corner Radius - 2 mm

Suqare End - Centre Cutting - 4 Fluted - TiAlN Coated

Model No. : SCCREM10X22X72X10XTIALNX2CR

About The Endmill :

1.

High Performance Solid Carbide Endmill - Always One Step Ahead in competition.

2.

Coated with TiAlN Coating

- The latest in recent PVD Coating Technology.

3.

Universal Geometry for all types of Metal Application –An

all round performing grade.

4.

Manufactured with Edge Corner Protection - No

worry for early corner chip off.

5.

Helix Angle 30°

6.

Made from Ultrafine Grade of Solid Carbide Rods – K20

7.

Flat Relief Angles on cutting edges suitable for wide range

of milling applications.

8.

Newly developed End Face Geometry for Long life Face Milling

– Exclusively available in “SHIVMAC” Endmills.

9.

Manufactured on Advanced & Latest 5 Axis CNC Tool &

Cutter Grinding machine.

10.

Hardness :: 55 hrc.

11.

Suggested Speed & Feed ( Parameter ) – RPM=1950 & Feed=900 mm/min

12.

Suggested = Maximum

Depth of Cut= 0.50 mm & Maximum

Width of Cut = 5.0 mm

13.

Diameter on Cutting Edges - Tolerance is maintained as per

h10 ( ISO286-2)

14.

Flute Length & Over all length Deviation is maintained

between +/_ 2.00 mm

15.

Diameter on Shank Length – Tolerance is maintained as per h6

( ISO286-2)

16.

Ovality & Taper on Shank length is maintained equal to

or below than 0.002 mm

17.

Tool measurement & analysis is randomly done on “Zoller”

for 10% production qty.

18.

Single piece plastic box packing with sponge along cutting

edges to avoid transport breakage/chip off.

19.

Un -Identical & Unique Tool number Laser marked on each

tool for correct traceability.

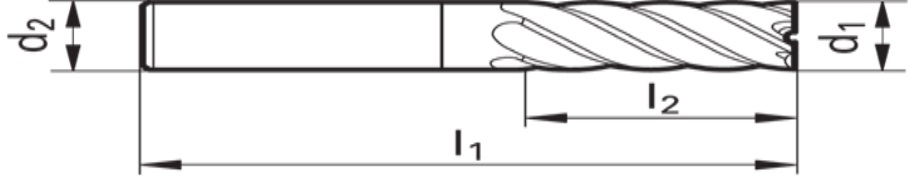

Drawing of The Solid Carbide Endmill : à Model No. : SCCREM10X22X72X10XTIALNX2CR

|

Cutting Diameter

(d1) |

Cutting Length (l2) |

Over All length (

l1) |

Shank Diameter (d2) |

Number of Flutes |

Coating Type |

Corner Radius |

|

10.0 mm (h10) |

22 mm |

72 mm |

10 mm (h6) |

04 |

TiALN |

2.00 mm |

-250x250h.jpg)

-250x250w.jpg)