Solid Carbide Drill - NTC - Ø 14.050 mm x 60 mm FL x 102 mm OAL x 14 mm Shank - AlTiN Coated -MAC2000 Grade - GP Series

- Stock: 1

- Model Number: SCD14.050x60x102x14-NTC-ALTIN-MAC2000(GP)

- Weight: 0.80kg

- Dimensions: 14.05mm x 60.00mm x 102.00mm

- SKU: 105

- UPC: 38623848836

- MRP: 19950.00

“SHIVMAC” Make

Solid Carbide Drill - NTC - Ø 14.050 mm x 60 mm FL x 102 mm OAL x 14 mm Shank - AlTiN Coated -MAC2000 Grade - GP Series

Catalogue Number ( Model No. ) : SCD14.050x60x102x14-NTC-ALTIN-MAC2000(GP)

PRODUCT FEATURES & TECHNICAL DETAILS

- High-Performance Solid

Carbide Drill

Designed for competitive machining environments requiring consistent and repeatable performance. - Advanced AlTiN PVD Coating

Latest-generation coating technology providing superior thermal resistance and extended tool life. - Universal Cutting Geometry

Optimized for a wide range of metallic materials, ensuring stable performance across diverse applications. - Reinforced Cutting Edge with

Corner Protection

Engineered to minimize premature edge chipping and improve operational reliability. - 30° Helix Angle

Optimized for balanced cutting action and efficient chip evacuation in general machining operations. - Ultrafine-Grain Solid

Carbide Substrate (K20 Grade)

Provides high wear resistance, edge stability, and dimensional consistency. - Manufactured on Advanced

5-Axis CNC Tool & Cutter Grinding Systems

Ensures precise geometry control and repeatable manufacturing quality. - Job Hardness Workability

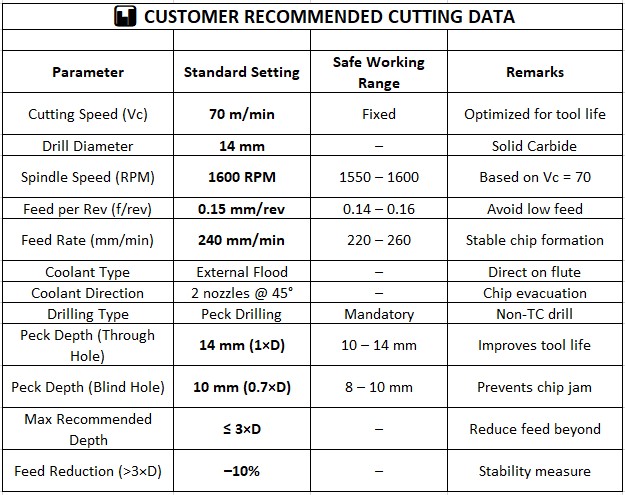

Up to 35 HRC of Job Hardness , optimized for strength and durability under industrial cutting conditions. - Recommended Cutting

Parameters

Spindle Speed: 1600 RPM

Feed Rate: 240 mm/min (0.150 mm/rev) - Cutting Diameter Tolerance

Maintained to h7 in accordance with ISO 286-2. - Flute Length & Overall

Length Tolerance

Controlled within ± 2.00 mm. - Shank Diameter Tolerance

Maintained to h6 in accordance with ISO 286-2. - Shank Ovality & Taper

Controlled to ≤ 0.002 mm to ensure precise clamping and concentricity. - Quality Inspection &

Measurement

Dimensional verification performed on Zoller pre-setting and measuring systems for randomly selected 10% of production output. - Protective Packaging

Individually packed in rigid plastic boxes with internal cushioning to prevent transport damage and edge chipping. - Laser Marking &

Traceability

Each tool is laser-marked with a unique identification number to ensure full production traceability.

SUITABLE WORK MATERIALS (UP TO 35 HRC)

✔

Mild Steel & Low Carbon Steel

✔

Medium Carbon Steel (EN8 / C45)

✔

Low & Medium Alloy Steel (Soft / Annealed)

✔

Austenitic Stainless Steel (304 / 316)

✔

Free-Cutting Steel

✔

Grey & Ductile Cast Iron

✔

Aluminium & Non-Ferrous Metals

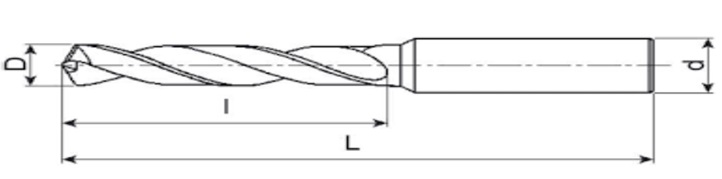

Drawing of The Solid Carbide Drill : à

Catalogue Number ( Model No. ) : SCD14.050x60x102x14-NTC-ALTIN-MAC2000(GP)

|

Cutting Diameter (D) |

Flute Length (I) |

Over All length ( L) |

Shank Diameter (d) |

Number of Flutes |

Coating Type |

Chamfer on Shank End |

|

14.050 mm (h7) |

60 mm |

102 mm |

14 mm (h6) |

02 |

AlTiN |

1.0 mm x 45° |

WHAT SHOULD CHANGE for Stainless Steel Hole Making (COMPARED TO STEEL ≤ 35 HRC)

|

KEY POINTS for S.S.

Application

✔ Stainless steel generates more heat

✔

Tends to work harden if speed is

high or feed is too low

✔

Slightly lower speed with healthy feed

gives best tool life

✔

Shorter peck prevents chip welding

⭐ RECOMMENDED SHOP-FLOOR SETTING (SS

304 / 316)

RPM:

1100

Feed: 165 mm/min

Feed / Rev: 0.15 mm

Peck: 10 mm

-250x250w.jpg)

COATED(1)-250x250w.jpg)

-250x250h.jpg)