Solid Carbide Endmill - Ø 6mm x 25mm FL x 70 mm OAL x Ø 6mm Shank - 4 F - MAC2000 GRADE, AlTiN Coated with Centre Cutting.

-550x550h.jpg)

- Stock: 60

- Model Number: SCEM6x25x70x6x4FxAlTiN

- Weight: 0.10kg

- Dimensions: 6.00mm x 25.00mm x 70.00mm

- MRP: 425.00

“SHIVMAC” Make

Solid Carbide Endmill - Ø 6mm x 25mm

FL x 70 mm OAL x Ø 6mm Shank - 4 F - MAC2000 GRADE, AlTiN Coated with

Centre Cutting.

Model No. : SCEM6x25x70x6x4FxAlTiN

Main Features :

1. High Performance Solid Carbide Endmill - Always One Step Ahead in

competition.

2. Coated with AlTiN Coating - The latest in PVD Coating Technology.

3. Special Geometry for all types of Metal Application.

4. Manufactured with Edge Corner Protection - No worry for

early corner chip off.

5. Helix Angle 30° - Most suitable for all types of Extreme Heat Generating

Milling applications.

6. Made from Finest Grade of Solid Carbide Rod.

7. Flat Relief Angles on cutting edges suitable for all types of Milling.

8. Latest developed End Face Geometry for Long life Face Milling.

9. Manufactured on Advanced & Latest 5 Axis CNC Tool & Cutter

Grinding machine.

10. Hardness :: ( workable Kobe material Hardness up to

) :: 40 hrc.

11. Suggested Speed & Feed ( Parameter ) – RPM=2600

Feed=750mm/min

12. Suggested = Maximum Depth of

Cut=0.6 mm & Maximum Width of Cut=3.00 mm

13. Suggested = Maximum Depth of

Cut=0.250 mm & Maximum Width of Cut = 3.5 mm

14. Diameter on Cutting Edges - Tolerance

is maintained as per h10 ( ISO286-2)

15. Flute Length & Over all length

Deviation is maintained between +/_ 2.00 mm

16. Diameter on Shank Length – Tolerance is

maintained as per h6 ( ISO286-2)

17. Ovality & Taper on Shank length is

maintained equal to or below than 0.002 mm

18. Tool measurement & analysis is

randomly done on “Zoller” for 10% production qty.

19. Single piece plastic box packing with

sponge along cutting edges to avoid transport breakage/chip off.

20. Un -Identical & Unique Tool number

Laser marked on each tool for correct traceability.

|

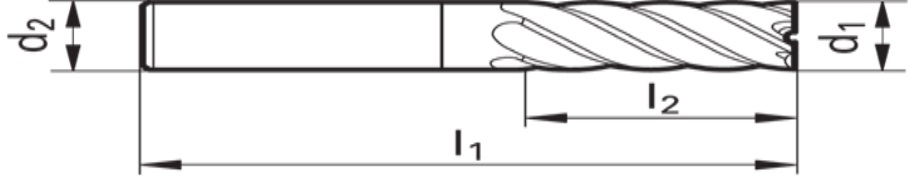

Cutting Diameter

(d1) |

Cutting Length (l2) |

Over All length (

l1) |

Shank Diameter (d2) |

Number of Flutes |

Coating Type |

Chamfer on Shank End |

|

6.0 mm (h10) |

25 mm |

70 mm |

6.0 mm (h6) |

04 |

TiAlN |

0.5 mm x 45° |

-250x250h.jpg)

-250x250w.jpg)